The supply chain historically has always had some amount of analytics. It has evolved from simple mathematical equations to complex statistical and probabilistic modeling in Excel to even more complex data science and machine learning models. I say evolved because the accuracy and use cases have gone up with every step. There’s even a separate field called Supply Chain analytics!

In a Gartner survey, supply chain executives have rated advanced analytics as the second most important emerging technology. It is used to stay a step ahead of the competition as it can be used for the following functions(and much more):

-Demand Prediction and Forecasting

-Inventory optimization

-Using chatbots and AI assistants for customer service

-Network Planning

-Logistics Analytics etc.

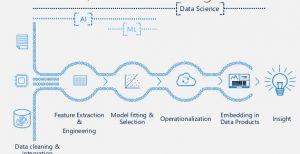

Capgemini’s supply chain offerings shed a light on some of the various possible areas where analytics can be used in Supply Chain Management:

Supply Chain 4.0 involves using IoT, advanced robotics, and Data Science and Analytics to optimize and automate processes wherever possible and understand the system better. According to a Gartner survey, 29% of the organizations say that they’ve achieved high levels of ROI compared to 4% who achieved no ROI. There are a lot of different softwares specifically for Supply Chain Analytics( Eg: SAP Supply Chain Analytics software, PeopleSoft Supply Chain Analytics) as well as general products for Supply Chain with Analytics and Data science capabilities.

Analyzing real-time data – geographic data to plan routes and reroute in case of emergencies, social media data for sentiment analysis, demand data to decide on how much to produce, etc can result in a more agile and pull-based supply chain which in turn can reduce waste and optimize resource utilization.

The first step in the supply chain management process is planning and demand forecasting is one of the main functions of this stage. Every step in the supply chain operates based on this forecast and getting good accuracy in this step can result in increasing the supply chain surplus(which is the main goal of supply chain management), reduce wastage, and increase profits. So let’s look into it in slightly more detail, shall we?

The two main outputs of demand forecasting are:

- Expected demand

- How much uncertainty there is in the prediction

To forecast demand in the future for a certain period of time, we will need past data and since this is clearly a time series forecasting problem, regression-based models and neural network-based models are the most effective.

Regression-based models include:

- ARIMA ( Autoregressive Integrated Moving Average )

- SARIMAX ( Seasonal Autoregressive Integrated Moving Average: an extension of ARIMA that supports univariate time series data with a seasonal component )

- Linear Regression

Neural Network-based models include:

- Artificial Neural Network ( Multi-Layer perceptron works well for demand forecasting )

- Convolutional Neural Network ( based on the type of problem: CNN models for univariate, multivariate, and multi-step time series forecasting can be developed)

- RNN ( LSTMs work well for time series problems )

In case you’re interested in using your data analytics and AI skills into the test and getting your hands dirty in demand prediction, here are two datasets that you can use: https://archive.ics.uci.edu/ml/datasets/Daily+Demand+Forecasting+Orders ,